-

more

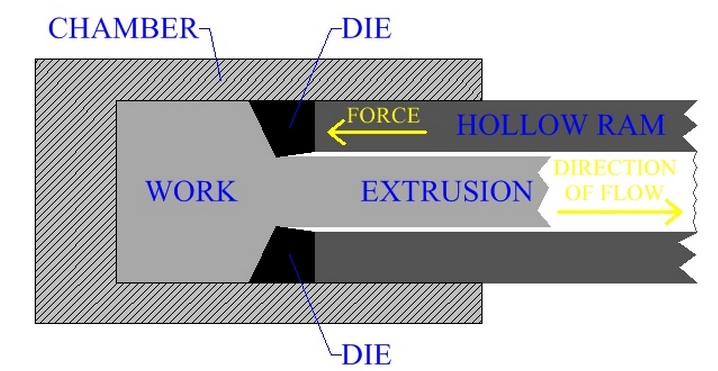

Indirect or Backward Extrusion

In the previous blog on Direct Extrusion, we had pointed the main disadvantage of direct extrusion being the excess use of force due to friction between the cylinder and billet. Accordingly, to deal with this issue, whenever possible one can use indirect or backward extrusion, wherein comparative lesser force is required for extruding the material.By BIadmin On Tuesday, December 10 th, 2013 · no Comments · In Blog -

more

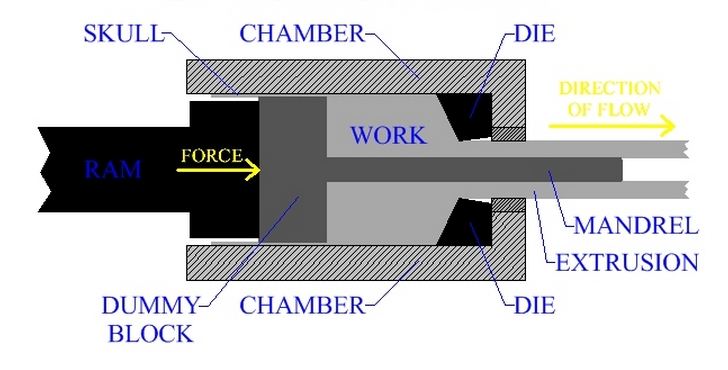

Direct or Forward Extrusion

As discussed in previous Blog on Extrusion Process, extrusion process are mainly of three types- Direct or Forward Extrusion, Indirect or Backward Extrusion & Hydrostatic Extrusion. This blog would speak on Forward or Direct Extrusion. Direct Extrusion, also known as forward extrusion or in-line compounding, is used greatly in production of semi-finished products including films, plates,By BIadmin On Thursday, December 05 th, 2013 · no Comments · In Blog -

more

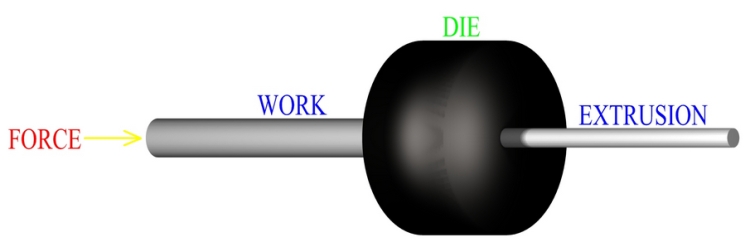

Extrusion Process

Extrusion is process used mostly to create a fixed, cross-sectional profile objects. It involves impounding the metal in a packed cavity and allowing it to later flow through the other opening. Consequently, the metal takes profile of the opening. The whole maneuver can be seen as identical to routine squeezing of toothpaste out of theBy BIadmin On Thursday, November 14 th, 2013 · no Comments · In Blog -

more

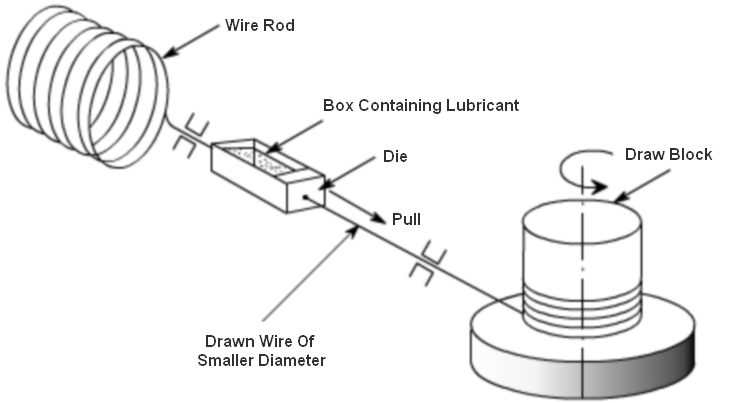

Wire Drawing

The usage of drawn wire is far beyond from everyday products like electrical wire & TV cables as well as paper clips and staples. It is used greatly in making springs of all kinds used in garage doors and other high tensile applications as well for making re-bar used in construction world-wide. Even spokes onBy BIadmin On Sunday, November 10 th, 2013 · no Comments · In Blog -

more

Tungsten Carbide

In the domain of stunning-infrastructure and sophisticated-machinery, Cemented Tungsten Carbide has emerged as the foremost choice for tools, dies and other wear parts. Once the optimum characteristics desired for the intended application are specified by the toolmaker or engineer, Tungsten Carbide can provide exceptional performance. Cemented Tungsten Carbide consists of Tungsten Carbide particles which areBy BIadmin On Thursday, August 29 th, 2013 · no Comments · In Blog -

more

Selection Of Right Die Material

The successful selection of appropriate raw material for using in die tools depends predominantly on the kind and size of wire being drawn. Even, the tonnage desired by the wire-drawer per die plays a vital role. Largely, a wire-drawer has to select between two raw-materials available for making die-tools, Tungsten Carbide & Polycrystalline Diamond(PCD). Generally,By BIadmin On Thursday, August 29 th, 2013 · no Comments · In Blog -

more

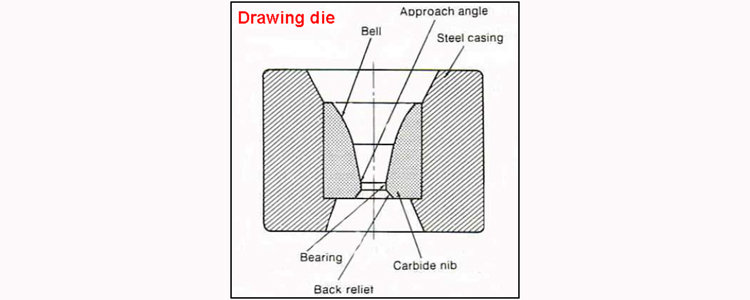

Drawing die sketch

Wire drawing involves reduction in the diameter of wire by elastic deformation achieved by passing it through a hole of smaller diameter whereas keeping the volume uniform. This tool having a small hole is called a die. The above sketch is of a typical Drawing die with its essential parameters. These dies can be usedBy BIadmin On Thursday, August 29 th, 2013 · no Comments · In Blog

Open Sidebar

Where we are?

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| « May | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

| 29 | 30 | |||||

Contact Us

Satish Singhal: (+91)-9820184994

Sales:

sales@wiredrawingdies.co.in

Information:

info@wiredrawingdies.co.in

General Enquiries:

bharatindustries10@gmail.com

Contact us

Satish Singhal: (+91)-9820184994

Sales:

sales@wiredrawingdies.co.in

Information:

info@wiredrawingdies.co.in

General Enquiries:

bharatindustries10@gmail.com

You can contact us via above email addresses or simply use quick enquiry form for a call back request (India only).

Quick enquiry

© Bharat Industries 2018