Services Offered

Wire drawing dies have to always be in perfect condition for producing consistent higher quality wires. The finest wire-drawing machines being operated by skilled personnel having best lubricant and wire material would fail to give good end-product, if the die bore hole doesn’t have ideal precision, geometry and surface. These issues with the die bore hole can be sorted by services like Recutting & Repolishing. Bharat Industries provides these essential Repolishing and Recutting services for all types of wire-drawing dies- Tungsten-Carbide, Synthetic Single Crystal Diamond and Polycrystalline Diamond dies.

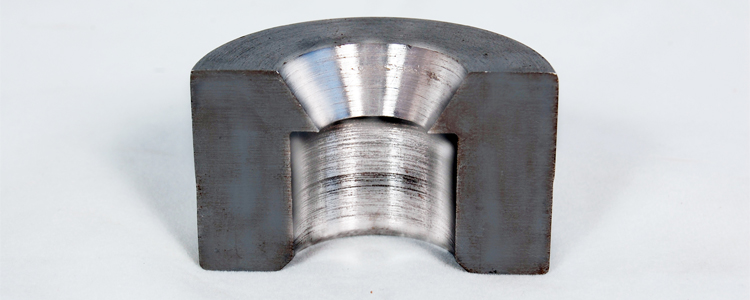

The usable life-span of a die depends on the geometry as well as the frictional and thermal loads it goes through while drawing. The finest and most durable hard-metal drawing die and the most compact diamond drawing die is bound to lose its flawless surface and eventually its geometry, mostly forming indents in reduction core/bearing region. A decline in excellence of wire drawn is symptomatic of initiation of wear in die being used. This is a clear sign for substitution of the drawing dies being used on an urgent basis.

Restoring the precision of drawing dies accurately cannot always be carried out within your own die-shop. You need to hire specialists having best working equipment with right working materials and calibrating instruments for the enlargement of diameter to be carried.

Wherever feasible and also defects are not severe, the dies are just Repolished removing all defects and keeping the original diameter, assuring a longer life-span.

In Certain cases, scratches and defects develop in the cylindrical as well as conical area of the die. Recutting eliminates any such defects and wear the die might have undergone and also recalliberate the die to new diameter suggested by the client. These services are carried out with the ultramodern technology, ensuring higher productivity and finest wire quality.