Extrusion Process

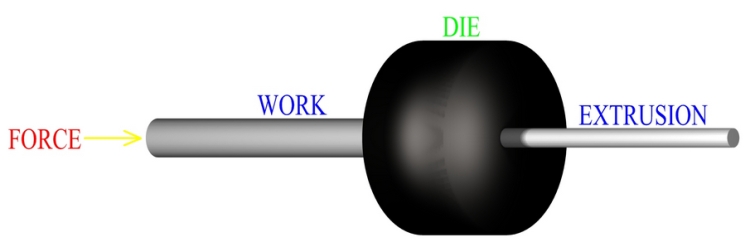

Extrusion is process used mostly to create a fixed, cross-sectional profile objects. It involves impounding the metal in a packed cavity and allowing it to later flow through the other opening. Consequently, the metal takes profile of the opening. The whole maneuver can be seen as identical to routine squeezing of toothpaste out of the toothpaste tube. The extrusion process can be either continuous, hypothetically producing indefinitely long material or can be semi-continuous making many products.

Process Of Extrusion:

One cannot create hollow cavities that easily within extruded material with a simple flat extrusion die. This is greatly due to fact that there would not be any support to the central barrier of the die. Hence, the extrusion die takes the shape of block with depth, having initially the geometrical-profile which supports centre section. Then, internally along its length the shape of die changes into final desired shape. Here, the suspended centre pieces are supported from back of die. Extrusion dies are generally made form tungsten carbide owing to its ability to resist wear, thereby being economical having a longer life. Hard materials, including metals are generally forced through the carbide extrusion dies to get final products.

Advantages:

The extrusion process has two major advantages as compared to other manufacturing processes:

- With extrusion it is easy to create complex cross-sections even with very brittle materials, as the material comes across only compressive and shear stresses.

- This process also achieves brilliant surface finish to the formed finished surfaces.

Extruded Materials:

Extrusion procedures can be carried out to obtain many complexes profiles as compared to rolling as the die is very simple and easily made. Also, a large amount of pressure can be applied in extrusion as compared to rolling. Extrusion processes can be carried out on brittle products to obtain sharp corners, different angles. Also, larger diameters, thin walled tubular products with perfect concentricity and tolerance can be produced with extrusion. Extrusion process can yield different cross sections depending on the inner shape within die. Most commonly found shapes include round, square, oval. Even special shapes like star, trapezium, hexagonal can be achieved

Extrusion can be applied to many materials including metals, ceramics, polymers, food stuffs. Metals commonly extruded include aluminum, copper, zinc, brass, steel. The foremost extruded metal is aluminum from which profiles for frames, mullions, tracks, rails and many more are achieved. Plastic extrusion can be carried out to produce chips or pellets which can later be dried and further used to feed screw. Ceramics can be given numerous shapes through extrusion. Terracotta extrusion is commonly done to produce pipes used in everyday life.

In further blogs we would discuss about three types of extrusion:

Bharat Industries has an experience of over 40 years in manufacturing extrusion tools including dies and tips. You may approach us for any of your requirement in metal extrusion and be rest assured to get the best services in town!

This entry was posted on Thursday, November 14th, 2013 at 3:43 pm and is belong to category Blog.