-

more

Cold Forming

Work Hardening also referred commonly as cold working or strain hardening process leads to strengthening of metal by its plastic deformation. The strengthening of metal is caused by the dislocation movements and dislocation generation occurring within the crystal structure of material. In metal-working processes, work-hardening stimulates plastic deformation to exact a shape change in metals.By BIadmin On Sunday, December 29 th, 2013 · no Comments · In Blog -

more

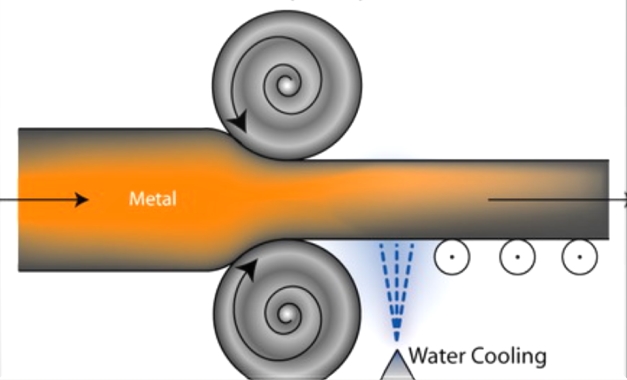

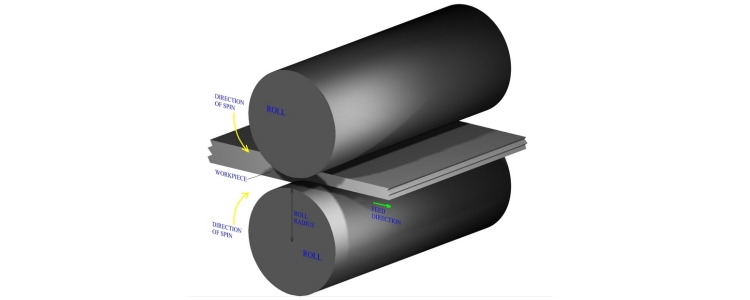

Metal Rolling

In today’s modern metal-world one can never lose foresight of metal rolling processes. Metal rolling is used in majority of metal-working processes making it the most important manufacturing process. In their manufacture, metals undergo rolling atleast at one point before final usage. Metal rolling is majority of times the first step in making raw materialsBy BIadmin On Wednesday, December 25 th, 2013 · no Comments · In Blog -

more

Stamping Dies

Metal Stamping and Metal Working Sheet metal stamping dies are used to produce high precision metal components which are identical in shape and size. The dimensional accuracy and stability which you can achieve using precision metal stamping dies are very high and thus metal stamping dies are integral part of any manufacturing industry. Stamping dieBy BIadmin On Wednesday, December 11 th, 2013 · no Comments · In Blog -

more

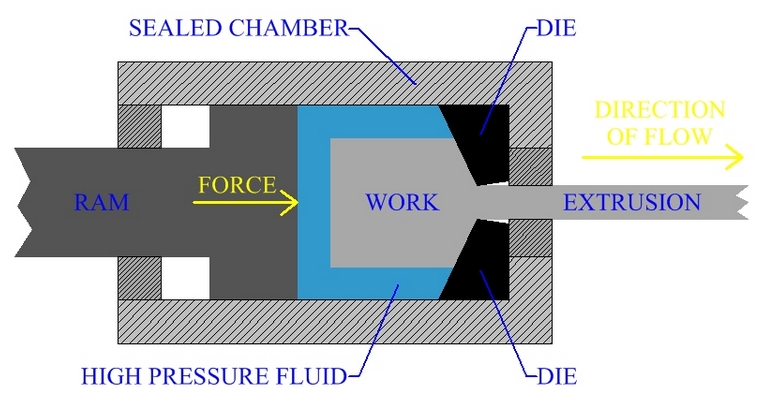

Hydrostatic Extrusion

In the previous blogs on extrusion and its types- Direct extrusion & Indirect Extrusion, it was noted that the major drawback with direct extrusion is the frictional forces acting on the billet. Accordingly, one can either try backward extrusion or can move ahead with hydrostatic extrusion. Hydrostatic extrusion is basically type of direct extrusion, whereinBy BIadmin On Wednesday, December 11 th, 2013 · no Comments · In Blog -

more

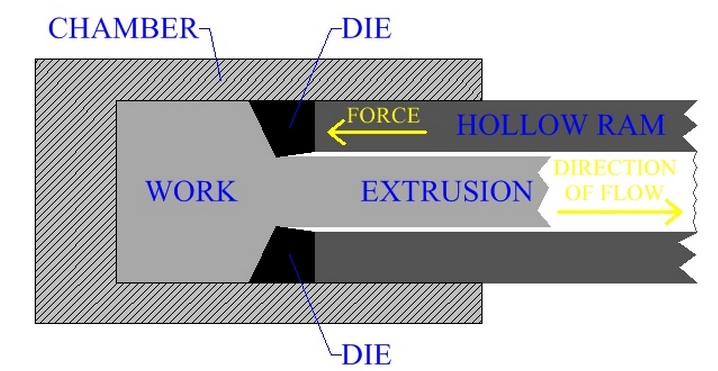

Indirect or Backward Extrusion

In the previous blog on Direct Extrusion, we had pointed the main disadvantage of direct extrusion being the excess use of force due to friction between the cylinder and billet. Accordingly, to deal with this issue, whenever possible one can use indirect or backward extrusion, wherein comparative lesser force is required for extruding the material.By BIadmin On Tuesday, December 10 th, 2013 · no Comments · In Blog -

more

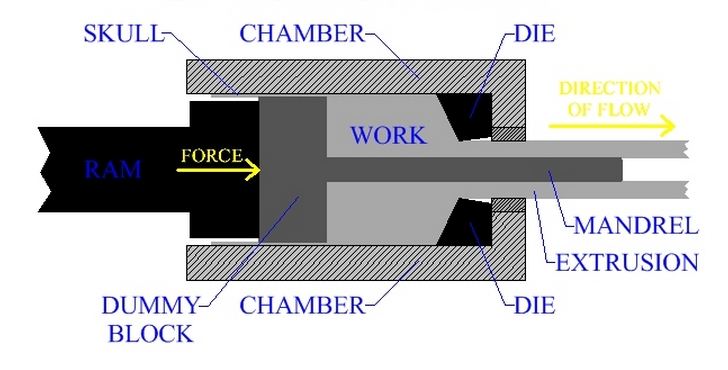

Direct or Forward Extrusion

As discussed in previous Blog on Extrusion Process, extrusion process are mainly of three types- Direct or Forward Extrusion, Indirect or Backward Extrusion & Hydrostatic Extrusion. This blog would speak on Forward or Direct Extrusion. Direct Extrusion, also known as forward extrusion or in-line compounding, is used greatly in production of semi-finished products including films, plates,By BIadmin On Thursday, December 05 th, 2013 · no Comments · In Blog

Open Sidebar

Contact Us

Satish Singhal: (+91)-9820184994

Sales:

sales@wiredrawingdies.co.in

Information:

info@wiredrawingdies.co.in

General Enquiries:

bharatindustries10@gmail.com

Contact us

Satish Singhal: (+91)-9820184994

Sales:

sales@wiredrawingdies.co.in

Information:

info@wiredrawingdies.co.in

General Enquiries:

bharatindustries10@gmail.com

You can contact us via above email addresses or simply use quick enquiry form for a call back request (India only).

Quick enquiry

© Bharat Industries 2018