Metal Rolling

In today’s modern metal-world one can never lose foresight of metal rolling processes. Metal rolling is used in majority of metal-working processes making it the most important manufacturing process. In their manufacture, metals undergo rolling atleast at one point before final usage. Metal rolling is majority of times the first step in making raw materials for further final product manufacturing. For example, the ingot or continuous casting is hot rolled into bloom or slabs, which act as basic structures for further usage. Rolling is most commonly carried at hot temperatures for better results.

Principles Of Metal Rolling

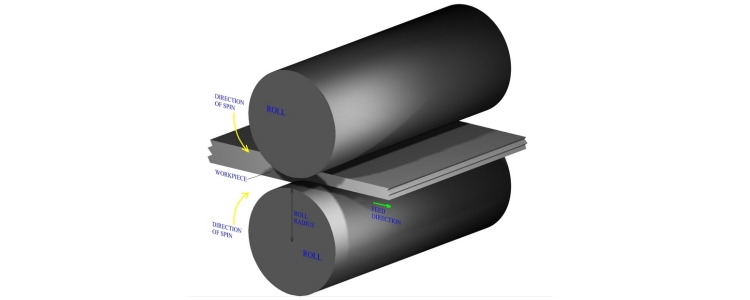

The basic principle of metal rolling involves passing the work material between two constantly spinning rolls to generate compressive forces for plastic deformation. These forces generated by constant movements of rolls reduce thickness of metal and also enhance its grain structure. The reduction in thickness can be calculated on basis of thickness before and thickness after rolling. This value is called draft. In addition to generation of force for causing reduction in thickness, these rolls also act as feeding agents, feeding the work material by their opposite direction movements with respect to each other.

Accordingly, friction becomes an essential factor in metal rolling. However, excess friction can be detrimental for various reasons. To help control the friction between the work material and the rolls during rolling process, numerous lubricants can be used. Metal rolling causes change in the geometrical profile of the work material keeping the volume intact.

Usage Of Metal Rolling

Metal rolling as said produces majority of the intermediate materials which are further processed for manufacturing final products. The blooms and slabs produced by rolling or ingot or continuous castings can be further rolled down to produce intermediate products including strip, coils, plates, bars, billets, rods and tubes. These intermediate products can further undergo various manufacturing processes including wire-drawing, forging, extrusion, sheet-metal working and machining. Coils can undergo wire drawing to produce wires used in making nails, horse-shoe, springs, wire-nets, wire-ropes. Blooms can be further processed to make H beams, T-sections, I Beams, channel beams used in structural applications. Rolled bar can be further used for making various simple and complex cross sections, used in machine building industries as well as in construction. Blooms can also be used for making rails used in producing railroad track. Even plates and sheets can be rolled from slabs and used in production of a variety of items.

This entry was posted on Wednesday, December 25th, 2013 at 2:21 pm and is belong to category Blog.