-

more

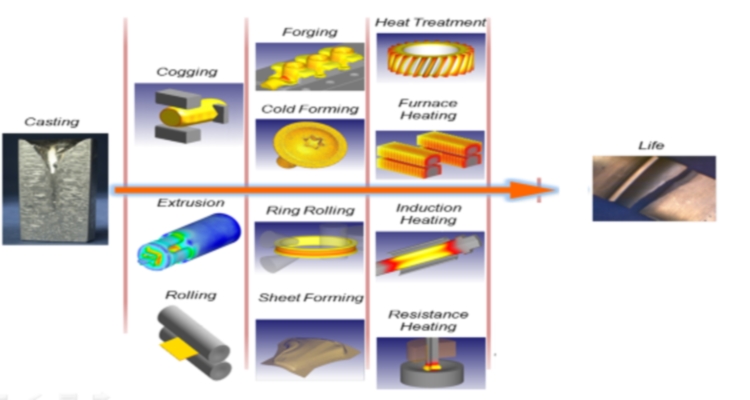

Metal Forming

Metal Forming, is a metalworking process of making metal parts and various objects by means of mechanical deformation. In this process, the workpiece is reshaped without any addition or reduction of material; keeping the mass unchanged. This process works on the phenomenon of plastic deformation, wherein the physical shape of the object is changed forever.By BIadmin On Tuesday, May 05 th, 2015 · no Comments · In Blog -

more

Metal Casting

Metal Casting can be addressed as the oldest manufacturing processes dating back nearly 6000 years. Theoretically, casting can be said filling a mold with molten material. This molten material upon solidification takes shape of the mold. Thus, within a single step, any kind of shape can be made from the molted metal as per theBy BIadmin On Wednesday, November 19 th, 2014 · no Comments · In Blog -

more

Manufacturing Processes

When we look around ourselves, we would notice that manufacturing processes are applicable in all sections of our lives. From the common means of transport like cars to the numerous food containers at our home, the television sets, computers all are manufactured by processes. This list goes on and on like power tools, aircons, pipesBy BIadmin On Wednesday, April 16 th, 2014 · no Comments · In Blog -

more

Hot Forming

In the blog before we spoke on cold working process which refers to strengthening of metal by plastic deformation at normal temperatures. In contrast, hot working refers to process where metals undergo plastic deformation at temperatures above their recrystallization point. This helps achieve the material to recrystallise during deformation. This is essential as recrystallization preventsBy BIadmin On Monday, February 17 th, 2014 · no Comments · In Blog -

more

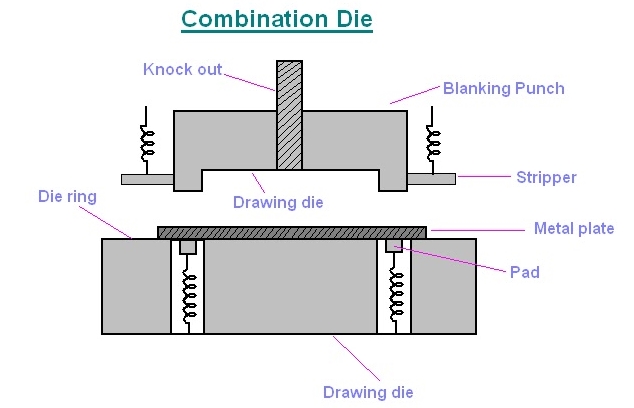

Dies Types 2

As discussed in previous blog on different types of dies, Dies can be categorized into sections based on type of operation and method of operation. The previous blog provided brief information on the different type of dies based on their method of operation. This blog gives further information on types of dies based on theirBy BIadmin On Tuesday, February 11 th, 2014 · no Comments · In Blog -

more

Die Types

The die is the basic heart of many manufacturing operations ranging from drawing to bending. Die can be defined as female part of a complete tool set used for producing work in press. It can be addressed as a complete tool set consisting of pair of mating members for producing work in a press. DiesBy BIadmin On Thursday, February 06 th, 2014 · no Comments · In Blog -

more

Cold Forming

Work Hardening also referred commonly as cold working or strain hardening process leads to strengthening of metal by its plastic deformation. The strengthening of metal is caused by the dislocation movements and dislocation generation occurring within the crystal structure of material. In metal-working processes, work-hardening stimulates plastic deformation to exact a shape change in metals.By BIadmin On Sunday, December 29 th, 2013 · no Comments · In Blog -

more

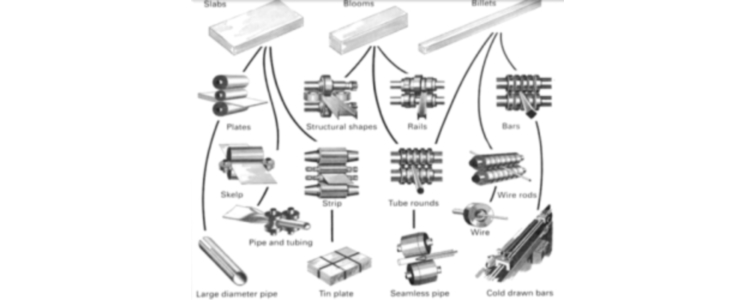

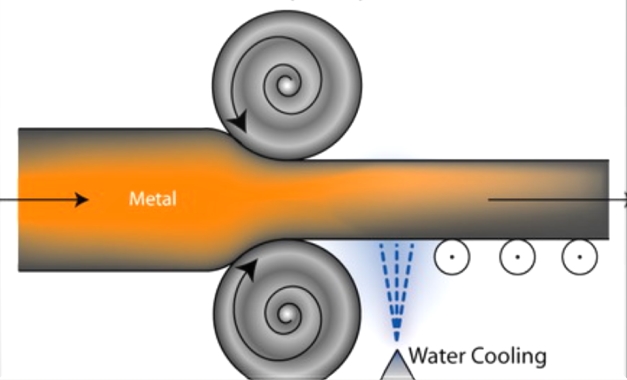

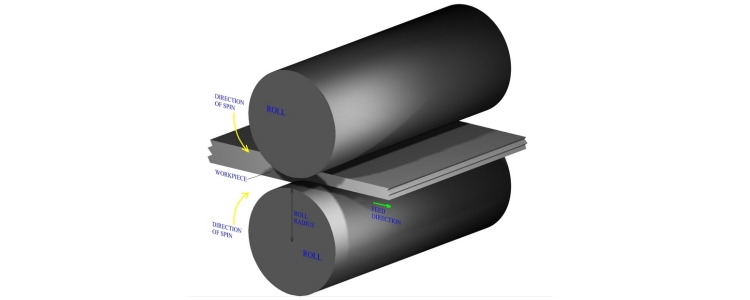

Metal Rolling

In today’s modern metal-world one can never lose foresight of metal rolling processes. Metal rolling is used in majority of metal-working processes making it the most important manufacturing process. In their manufacture, metals undergo rolling atleast at one point before final usage. Metal rolling is majority of times the first step in making raw materialsBy BIadmin On Wednesday, December 25 th, 2013 · no Comments · In Blog -

more

Stamping Dies

Metal Stamping and Metal Working Sheet metal stamping dies are used to produce high precision metal components which are identical in shape and size. The dimensional accuracy and stability which you can achieve using precision metal stamping dies are very high and thus metal stamping dies are integral part of any manufacturing industry. Stamping dieBy BIadmin On Wednesday, December 11 th, 2013 · no Comments · In Blog -

more

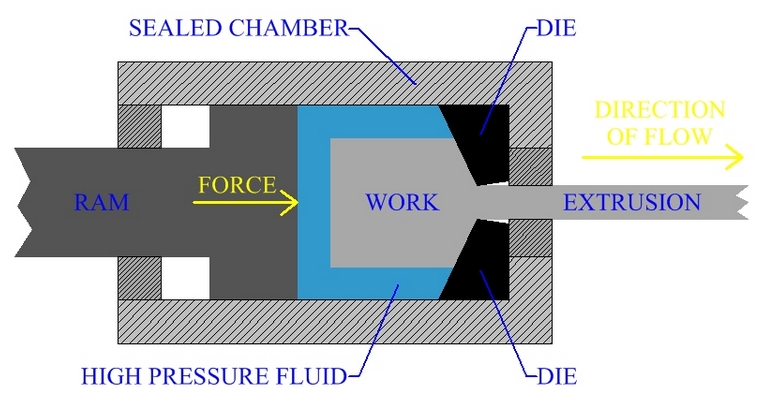

Hydrostatic Extrusion

In the previous blogs on extrusion and its types- Direct extrusion & Indirect Extrusion, it was noted that the major drawback with direct extrusion is the frictional forces acting on the billet. Accordingly, one can either try backward extrusion or can move ahead with hydrostatic extrusion. Hydrostatic extrusion is basically type of direct extrusion, whereinBy BIadmin On Wednesday, December 11 th, 2013 · no Comments · In Blog

Open Sidebar

Where we are?

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| « May | ||||||

| 1 | 2 | 3 | 4 | 5 | ||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 27 | 28 | 29 | 30 | 31 | ||

Contact Us

Satish Singhal: (+91)-9820184994

Sales:

sales@wiredrawingdies.co.in

Information:

info@wiredrawingdies.co.in

General Enquiries:

bharatindustries10@gmail.com

Contact us

Satish Singhal: (+91)-9820184994

Sales:

sales@wiredrawingdies.co.in

Information:

info@wiredrawingdies.co.in

General Enquiries:

bharatindustries10@gmail.com

You can contact us via above email addresses or simply use quick enquiry form for a call back request (India only).

Quick enquiry

© Bharat Industries 2018